1. Kuhlatiya sakhiwo

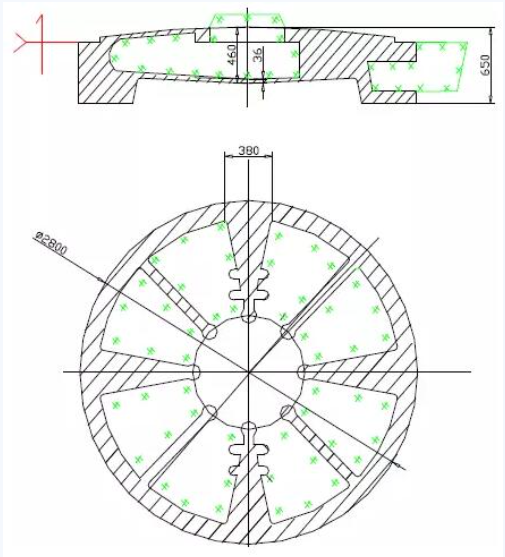

(1) Loku .ivalvu yevivaneinesakhiwo lesiyindingilizi lesimise kwelikhekhe, umgodzi wangekhatsi uxhunywe futsi usekelwe timbambo leticinisako letingu-8, imbobo lesetulu ye-Φ620 ikhulumisana nemgodzi wangekhatsi, bese konkhe lokusele kweivalvuivaliwe, umgogodla wesihlabathi kumatima kuwulungisa futsi kulula kukhubateka. Kokubili i-ekzosi kanye nekuhlantwa kwemgodzi wangekhatsi kuletsa bumatima lobukhulu, njengoba kukhonjisiwe kuMfanekiso 1.

Kucina kwelubondza lwema castings kuyahluka kakhulu, kucina kwelubondza lokukhulu kufika ku 380mm, bese kucina kwelubondza lokuncane ku 36mm kuphela. Uma le casting icinile, umehluko wekushisa mkhulu, futsi kuncipha lokungalingani kungakhicita kalula imigodzi yekuncipha kanye nekuncipha kwema porosity, lokutawubangela kugeleta kwemanti ekuhlolweni kwe hydraulic.

2. Umklamo wenchubo:

(1) Lendzawo yekuhlukana ikhonjiswe ku Figure 1. Faka siphetfo lesinetimbobo ebhokisini lelisetulu, yenta umgogodla wesihlabathi wonkhe emgodzini losemkhatsini, bese ukhulisa inhloko yemgogodla ngendlela lefanele kwentela kubelula kubopha umgogodla wesihlabathi kanye nekuhamba kwemgogodla wesihlabathi uma lelibhokisi liguculwa. Kuzinzile, budze benhloko ye cantilever core yetimbobo letimbili letiyimphumphutse eceleni budze kunebudze bembobo, kwentela kutsi sikhungo semandla ladonsela phansi sayo yonkhe inhloko yesihlabathi sibe nelubandlululo eceleni kwenhloko yesihlabathi kwentela kucinisekisa kutsi umgogodla wesihlabathi ucinile futsi uzinzile.

Luhlelo lwekutfulula loluvaliwe luyamukelwa, ∑F ngekhatsi: ∑F lovundlile: ∑F locondzile=1:1.5:1.3, le sprue isebentisa lishubhu lebumba lelinebubanti bangekhatsi be Φ120, kanye netincetu letimbili te 200 × 100 yfractor × 40mm tibekwa emabhokisini insimbi kusuka ngco Kute umtselela sikhunta sihlabathi, i 150 × 150 × 40 foam ceramic luhlu lufakwa phansi umgijimi, kanye 12 emashubhu ceramic nge ububanzi bangaphakathi Φ30 asetjentiselwa umgijimi wangekhatsi ukuxhuma ngokulingana phansi ukuhlunga form at the bolleu t . luhlelo lwekutfululela, njengobe kukhonjisiwe kuMfanekiso 2 Umcondvo .

(3) Beka 14 ∮20 imbobo umoya imbobo esikhunjini lesingetulu, beka Φ200 sihlabatsi core vent imbobo emkhatsini core inhloko, beka insimbi ebandzayo etincenyeni letindze naletinkhulu kucinisekisa kucinisa lokulinganiselwe kwekulahla, bese usebentisa inqubo yekwandziswa kwe-graphitization ku-improve is. Usayizi welibhokisi lesihlabathi ngu 3600×3600×1000/600mm, futsi lishiselwe ngepuleti lensimbi lebukhulu lobungama 25mm kwentela kucinisekisa emandla lanele kanye nekucina, njengoba kukhonjisiwe kuMfanekiso 3.

3. Kulawula inchubo

. kusuka ekutsintseni incenye yemgijimi sikhatsi lesidze kubangela kugeza kwesihlabathi.

Kwenta umgogodla: Umgogodla wesihlabathi uhlukaniswe waba tincenye letingu 8 letilinganako ngetimbambo leticinisako letingu 8, letihlanganiswa ngemgodzi losemkhatsini. Kute letinye tincenye tekusekela kanye nekukhipha ngaphandle kwenhloko lesemkhatsini lesemkhatsini. Uma umgogodla wesihlabathi ungakhoni kulungiswa kanye ne Exhaust, kuhamba kwemgogodla wesihlabathi kanye netimbobo temoya kutawuvela ngemuva kwekutfulula. Ngenca yekutsi indzawo yonkhe ye-sand core inkhulu, ihlukaniswe yaba tincenye letisiphohlongo. Kumele ibe nemandla lanele kanye nekucina kwentela kucinisekisa kutsi umgogodla wesihlabathi angeke ulimale ngemuva kwekukhishwa kwesikhunta, futsi angeke ulimale ngemuva kwekutfulula. Deformation kwenteka, kute kucinisekiswe umfaniswano lubondza ubukhulu ukulahla. Ngalesizatfu, sakha ngalokukhetsekile litsambo leliyinhloko, futsi salibopha kulelitsambo leliyinhloko ngentsambo yekungenisa umoya kwentela kudvweba igesi lekhiphako kusuka enhloko lesemkhatsini kwentela kucinisekisa kuhlanganiswa kwesikhunta sesihlabathi uma senta umgogodla. Njengobe kukhonjisiwe kuMdvwebo 4.

(4) Libhokisi lekuvala: Ngekucabanga kutsi kumatima kuhlanta sihlabatsi emgodzini wangekhatsi we valve ye butterfly, wonkhe umgogodla wesihlabathi upendwe ngetinhlavu letimbili tepende, lucwencwe lwekucala lubhushwa ngepende ye zirconium lesekelwe etjwaleni (Baume degree 45-55), bese lucwencwe lwekucala lupendwa nge burne. Ngemuva kwekomisa, penda lesendlalelo sesibili ngepende ye magnesium lesekelwe etjwaleni (Baume degree 35-45) kuvikela lokulahlwa kutsi kunganamatsele esihlabathini kanye nekuvuvuka, lokungeke kuhlantwe. Lencenye yenhloko leyinhloko ilengiswa ephayiphini lensimbi le Φ200 lesakhiwo lesikhulu selitsambo leliyinhloko ngetikulufu letintsatfu te M25, ilungiswa futsi ikhiywe ngelibhokisi lesihlabathi lesikhunta lelingetulu lelinetikulufu bese ihlolwa kutsi ngabe bukhulu belubondza lwencenye ngayinye buyafana yini.

4. Inchubo yekuncibilikisa nekutfulula

(1) Sebentisa iBenxi lephansi-P, S, Ti lesezingeni leliphakeme Q14 / 16 # insimbi yengulube, bese uyifaka ngesilinganiso se-40% ~ 60%; tintfo letilandzelanako letifana ne P, S, Ti, Cr, Pb, njll tilawulwa kakhulu ensimbini lelahliwe, futsi kute umhlwa kanye ne oyili lokuvumelekile , silinganiso sekwengeta ngu 25%~40%; lelishaja lelibuyiselwe kumele lihlantwe ngekudubula ngaphambi lisetjentiswe kwentela kucinisekisa kuhlanteka kwalelicala.

(2) Kulawula kwetincenye letiyinhloko ngemuva kwesithando: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (insalela): 0.035% ~ 0.05%, ngaphansi kwemkhawulo we-s. (insalela) kufanele kutsatfwe ngendlela lekhonakala ngayo.

(3) Kulashwa kwekugoma kwe spheroid: kusetjentiswa ema spheroidzers laphansi-magnesium kanye nemhlabatsi longakavami, futsi silinganiso sekwengeta ngu 1.0% ~ 1.2%. Indlela levamile yekuhlanta kwelashwa kwe spheroidization, 0.15% wekugoma kwesikhatsi sinye kumbonywe ku nodulizer lephansi kwephakheji, bese kwenta spheroidization kuyacedvwa. Le slag ibese iyatsatfwa ngephansi kwentela kugonywa kwesibili kwa 0.35%, bese kugonywa kwekugeleta kwa 0.15% kwentiwa ngesikhatsi sekutfululwa.

(5) Low lokushisa fast inchubo yamukelwa, lokushisa kutfulula 1320 ° C ~ 1340 ° C, kanye nesikhatsi kutfulula 70 ~ 80s. Lensimbi lencibilikile ayikhoni kuphazamiseka ngesikhatsi sekutfulula, futsi lenkomishi ye sprue ihlale igcwele kuvikela igesi kanye nekufakwa kutsi kungahlanganyeli kulesikhunta ngekusebentisa umgijimi. imbobo.

5. Imiphumela yekuhlolwa kwekukhipha

(1) Hlola emandla e-tensile ebhulokhi yekuhlola lephosiwe: 485MPa, kukhula: 15%, Brinell bucina HB187.

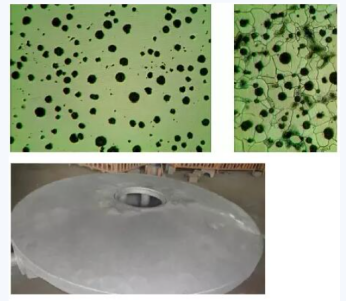

(2) Lizinga lekukhicita liyindingilizi ngu 95%, bukhulu be graphite libanga 6, bese i pearlite ngu 35%. Lesakhiwo setinsimbi sikhonjiswe kuMfanekiso 5.

(3) Kute emaphutsa labhalwe phansi latfolakala ku-UT kanye ne-MT yesibili yekutfola emaphutsa etincenye letibalulekile.

(4) Kubukeka kusicaba futsi kuyashelela (bona Umfanekiso 6), ngaphandle kwemaphutsa ekulahlwa njengekufakwa kwesihlabathi, kufakwa kwe slag, kuvalwa lokubandzako, njll, bukhulu belubondza buyafana, futsi tilinganiso tihlangabetana netidzingo temidvwebo.

(6) 20kg / cm2 hydraulic umfutfo test ngemuva kwekucubungula akuzange kukhombise noma ngukuphi kuvuza

6. Siphetfo

Ngekuya kwetimphawu tesakhiwo sale valve yeluvivane, inkinga yekungasimami kanye nekugucuka lokulula kwemgogodla lomkhulu wesihlabathi emkhatsini kanye nekuhlantwa kwesihlabathi lokumatima kucatululwa ngekugcizelela ekwakhiweni kweluhlelo lwenchubo, kukhicita kanye nekulungisa umgogodla wesihlabathi kanye nekusetjentiswa kwetintfo letisekelwe ku-zirconium. Kubekwa kwetimbobo tekukhipha umoya kugwema kungenteka kwema-pores kuma-castings. Kusuka ekulawuleni kwekushaja kwesitofu kanye neluhlelo lwekugijima, sikrini sekuhlunga se-foam ceramic kanye nebuchwepheshe be-ceramic ingate kusetjentiswa kucinisekisa kuhlanteka kwensimbi lencibilikile. Ngemuva kwekwelashwa lokunyenti kwekugoma, sakhiwo se-metallographic se-castings kanye netinhlobonhlobo Kusebenta lokuphelele sekufinyelele etidzingo letijwayelekile temakhasimende .

KusukelaI-Tianjin Tanggu Ivalvi yekuvala emanti. Ivalvu yevivane, ivalvu yesango, Y-sisefo, wafer emapuleti lamabili ekuhlola ivalvukukhicita.

Sikhatsi sekuposa: Indlovana-29-2023